Products

Continuous Operation Type Dry Bead Mill

DRYSTAR SDA1

The Only table-sized Continuous Dry Bead Mill in the Industry

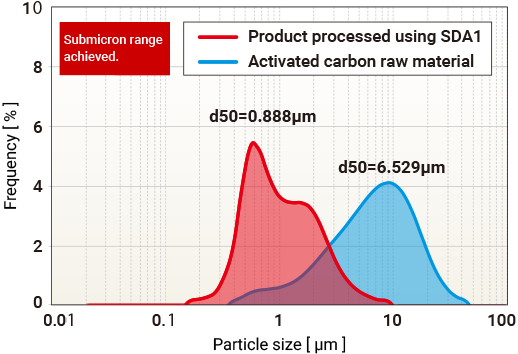

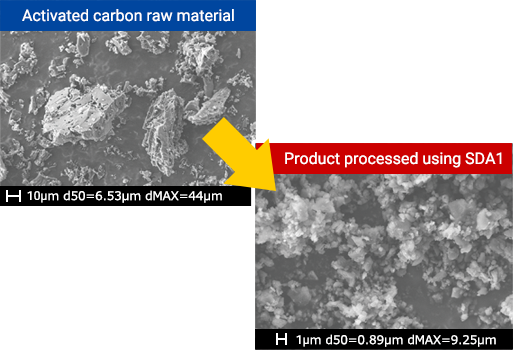

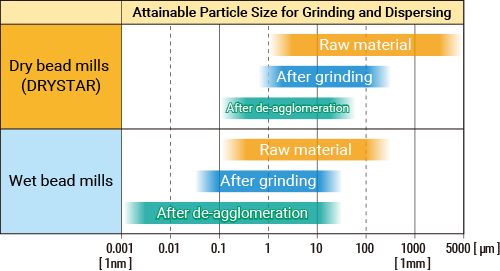

The DRYSTAR SDA1 achieves submicron-size particles by dry grinding without classifiers.

This machine has a 100 times better grinding ability compared to ball mills.

A trial can be started from 0.5L as a minimize volume.

User friendly design.

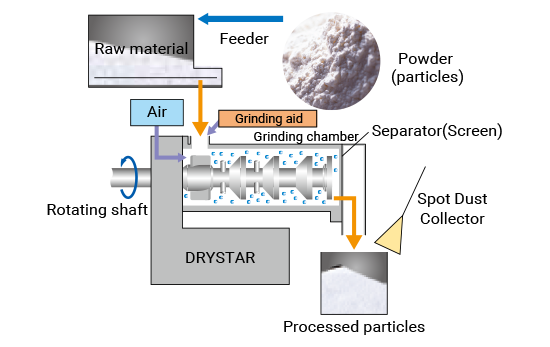

Structual drawing / Feature

- Achieving submicron-size particles by dry grinding

- Capable of testing 0.5 L as a minimum sample volume

- Particle diameter of 10 μm at maximum without using classifiers

- 100 times better grinding ability compared to ball mills

Process Examples

| Dry bead mills (DRYSTAR) |

Wet bead mills | |

|---|---|---|

| Bead diameter | Φ1.5 – 8mm | Φ0.03 – 2mm |

| Shaft seal | Easy (Oil seal・Air seal) |

Precision (Mechanical seal) |

| Material wear | Low (1/10, Compared with wet processing) |

High |

| Re-agglomeration | More likely | Less likely |

| Particle compounds | Good | Possible |

| Mechanochemical effect | Large | Extremely small |

Application

| Mohs hardness | Materials |

|---|---|

| 7 – 9 | Quartz, Silica, soft ferrites, Hard ferrites, Carrier ferrites, Alumina, Silicon nitride, Iron oxide, Tungsten oxide, Sodium silicate |

| 4 – 6 | Glass, Carbon, Black silica, Blast furnace ash, Fly ash, Burned ash, Organogermanium |

| Less than 4 | Gypsum, Magnesium hydroxide, Aluminum hydroxide, Barium titanate, PZT, Powdered green tea, Rice flour |

Model Sizes -from the laboratory to large-scale production

| Model | SDA1 – SDA500 |

|---|---|

| Drive【kW】 | 3.5kW – 200kW |

| Grinding chamber volume | 1.0L – 500L |

| Bead diameter | φ1.5 – 8mm |