Technology

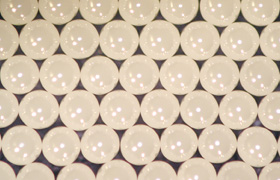

MLCC

(Multi Layered Ceramic Capacitor)

Uniformly dispersing particles on the basis of ideal movements of beads without over-dispersion (mild dispersion)

Reduced size and increased capacity

- Size reduction and increase in capacity

- Production of high-purity, fine and uniform dielectric materials

- Control of particle size

Materials

- Materials for the MLCC

- Barium titanate and nickel( BaTiO3, Ni )

- Materials for other electronic components

- Ferrites (iron oxide), inductors, conductive paste, thermistors, varistors and noise filters

Functions needed

- Control of chipping

- Reduction of contamination

- Maintenance of characteristics of particles

- Control of re-agglomeration

Recommended products

- The MAX NANO GETTER performs mild dispersion into primary particles without changing their forms.

- The SDA grinds particles to micron sizes without use of solvent.

All-Solid-State-Battery

(solid electrolytes)

Achieves a sharp particle size distribution through high-flow recirculation

Purposes of grinding

- Control of sintering temperature

- Uniform dispersion of multiple particle types

- Product size reduction

Materials

- Materials for solid electrolyte

- Silica and sulfides

- Materials for other lithium-ion secondary batteries

- Manganese oxide, cobalt oxide, lithium carbonate, hard carbon, artificial graphite, conductive carbon black, graphite and alumina

Functions needed

- Minimized wear and contamination control

- Sharp particle size distribution

Recommended products

- The MAX NANO GETTER performs mild dispersion into primary particles without changing their forms.

- The SDA grinds particles to micron sizes without the use of solvent.

Anti-Glare Films

(High refractive index coating material)

Evenly dispersing into transparent sizes while maintaining characteristics of translucent fine particles

Purposes of grinding

- Glare and reflection prevention for displays

- Increase in transparency of transparent fine particles

Materials

Silica, alumina and zirconia

Functions needed

- Dispersion without altering particle characteristics? and morphology/li>

- Uniform grinding of particles

- Grinding into nano sizes

Recommended products

- The MAX NANO GETTER performs mild dispersion into primary particles without changing their forms.

- The SDA dry bead mill grinds particles to micron sizes without the use of solvent.

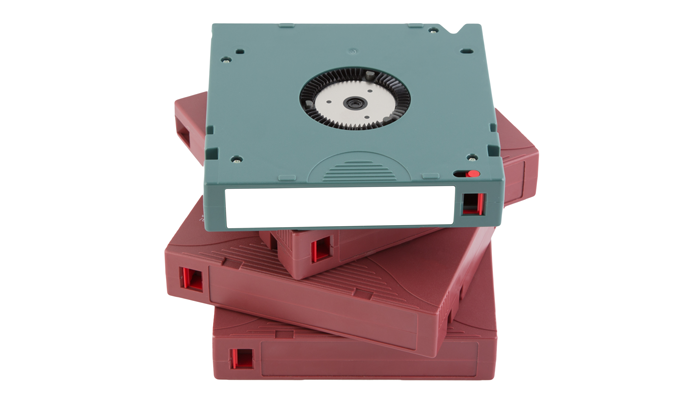

Magnetic Recording Materials

(LTO tapes)

Evenly dispersing magnetic particles

Purposes of grinding

- Increase in recording capacity

- Longer-term data storage

- Film thickness reduction (making thin coating)

- Noise reduction

Materials

Barium ferrite, soft magnetic materials, hard magnetic materials, iron oxide (ferrites and maghemite) and cobalt.

Functions needed

- Dispersion without affecting characteristics and forms of particles

- Uniform grinding of particles

- Grinding into nano sizes

Recommended products

- The MAX NANO GETTER performs mild dispersion into primary particles without changing their forms.

- The SDA grinds particles to micron sizes without the use of solvent.